Multi-axis

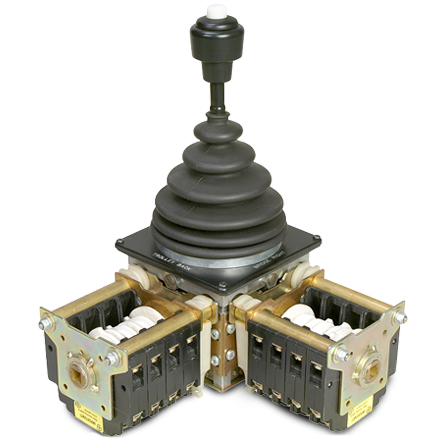

1,2 & 3 Axis mill-duty Joystick supports horizontal, vertical and tandem mounting of contact drives. In applications where mounting space is limited, customers benefit from the ability to configure the contact drives to suit the available space.

Rugged construction with nickel chromium gimbal mechanism, case hardened bearings and operating shaft

Supports horizontal, vertical and tandem mounting of contact drives to suit the available installation space

Stepless or stepped control with up to 7-0-7 detents

Environmentally sealed panel mounting

• Single

• Dual

• Three

Three Axis

Third axis is achieved via a twist handle function or thumbwheel.

• Contacts

• Potentiometer

• Encoder

• 4-20mA

• Transformer

• Open Gate

![]()

Open Gate

Unrestricted handle travel up to +/- 36°

• Cross Gate

![]()

Cross Gate

Guided handle travel up to +/- 36°

• Custom Gate

![]()

Custom

Available upon request in pattern of your choice

• Spring Return

Spring Return

Handle returns to center

• Maintained

![]()

Maintained

Handle holds at detent steps

• Friction Brake

![]()

Friction Brake

Handle holds throughout

• Panel (From Below)

The VNSO Joystick is utilized in heavy-duty cycle applications where life and durability is essential. Typical applications include:

Cranes (STS, RTG, overhead, foundry, portal, & more)

Steel mill process control

Logging

Mining machinery

Offshore drilling equipment

And more

Download

# of Axis

Output Options

Joystick Action

Handle Travel

Gate

Max # of Steps

Handle Compatibility

Life

Materials

Est. Shipping Weight

Est. Shipping Dimensions

Mounting Style

Mounting Footprint

IP Rating

Operating Temperature

Storage Temperature

Contact Specifications

Additional Specifications

Compact and rugged with a plastic zytel body. Ideal for heavy duty applications where space is limited.

Compact and rugged with a plastic zytel body. Ideal for heavy duty applications where space is limited.

Often described as an oversized VNSO, the VNS2 offers the highest level of durability and ruggedness.

Often described as an oversized VNSO, the VNS2 offers the highest level of durability and ruggedness.

Shares the same rugged construction and long-life as the standard VNSO, but in a more compact size. Available with microswitches, hall-effect & PWM output types.

Shares the same rugged construction and long-life as the standard VNSO, but in a more compact size. Available with microswitches, hall-effect & PWM output types.